Dinamic Emballages expertise

The skills and expertise of Dinamic Emballages’ teams make it the partner of demanding companies in plastic injection moulding sector.

Dinamic Emballages has a design office and an R&D department.

Projects start with a preliminary design and a feasibility study. The high level of control of the manufacturing processes makes it possible to guarantee a precise costing of the project, from the preliminary design to production.

All projects are subject to precise specifications and planning so that the order can be checked, managed and executed in the best way possible within the agreed deadlines.

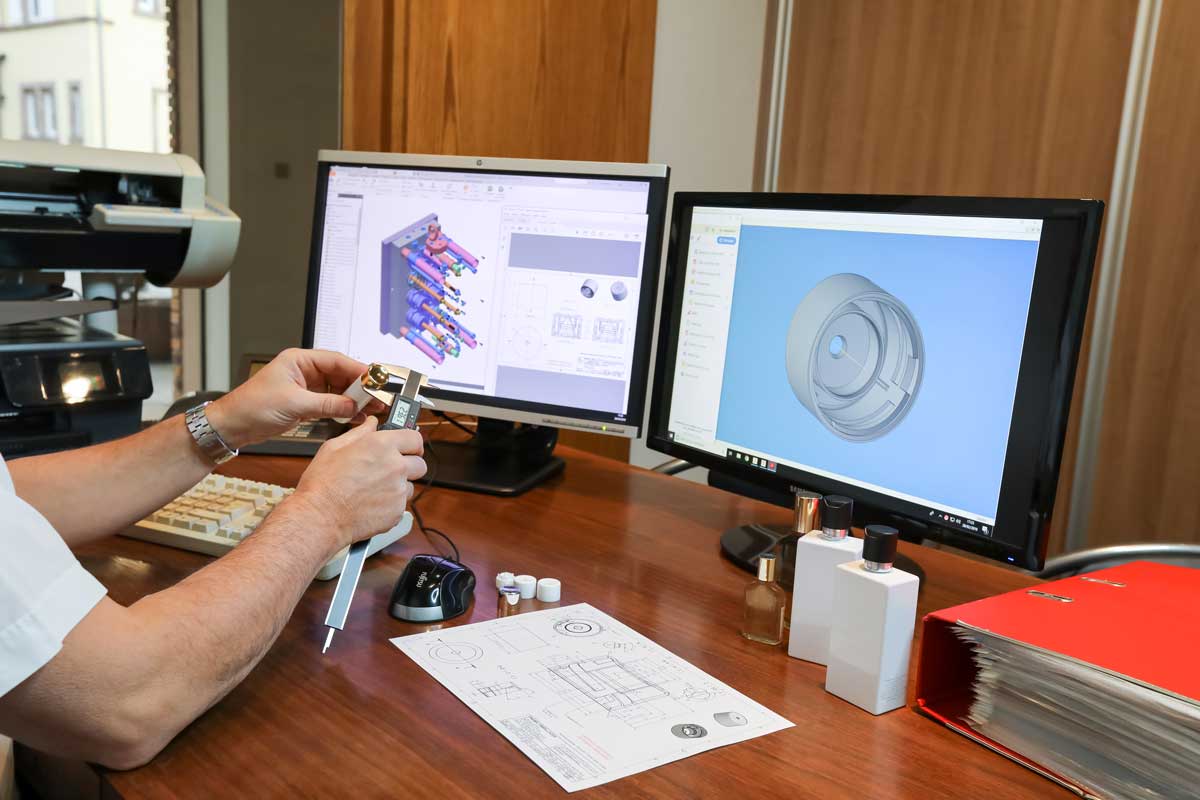

CAD design office

Dinamic Emballages provides its customers with a dedicated design office equipped with 2D and 3D computer-aided design and drawing software which is used to develop projects, design specific products and create technical plans validated by 3D prototypes.

Controlled production

The next step is to make the mould. Dinamic Emballages ensures the project management of the mould, from order to commissioning after the customer has confirmed the initial samples.

At this stage, the Dinamic Emballages teams give their customers a real bonus.Its expertise and partnerships with external service providers are an added value and guarantee a top-quality mould.

All these steps are validated as part of a gradual and integrated quality approach. Once fully costed and planned, your orders can start being produced.

Dinamic Emballages invests its skills, resources and expertise in the success of your projects and orders.

.