Special connector workshops

Dinamic Emballages can meet all requirements. Its expertise is shown in the production of thermoplastic technical parts requiring assembly and the addition of connectors.

To respond to these specific requests, Dinamic Emballages has set up special workshops for installing connectors.

In fact, like each order placed with the company, the process is subject to precise and detailed specifications for the service.

Controlled and monitored processes

1. – Preparing the parts:

- injecting technical parts,

- purchase, receipt and inspection of components,

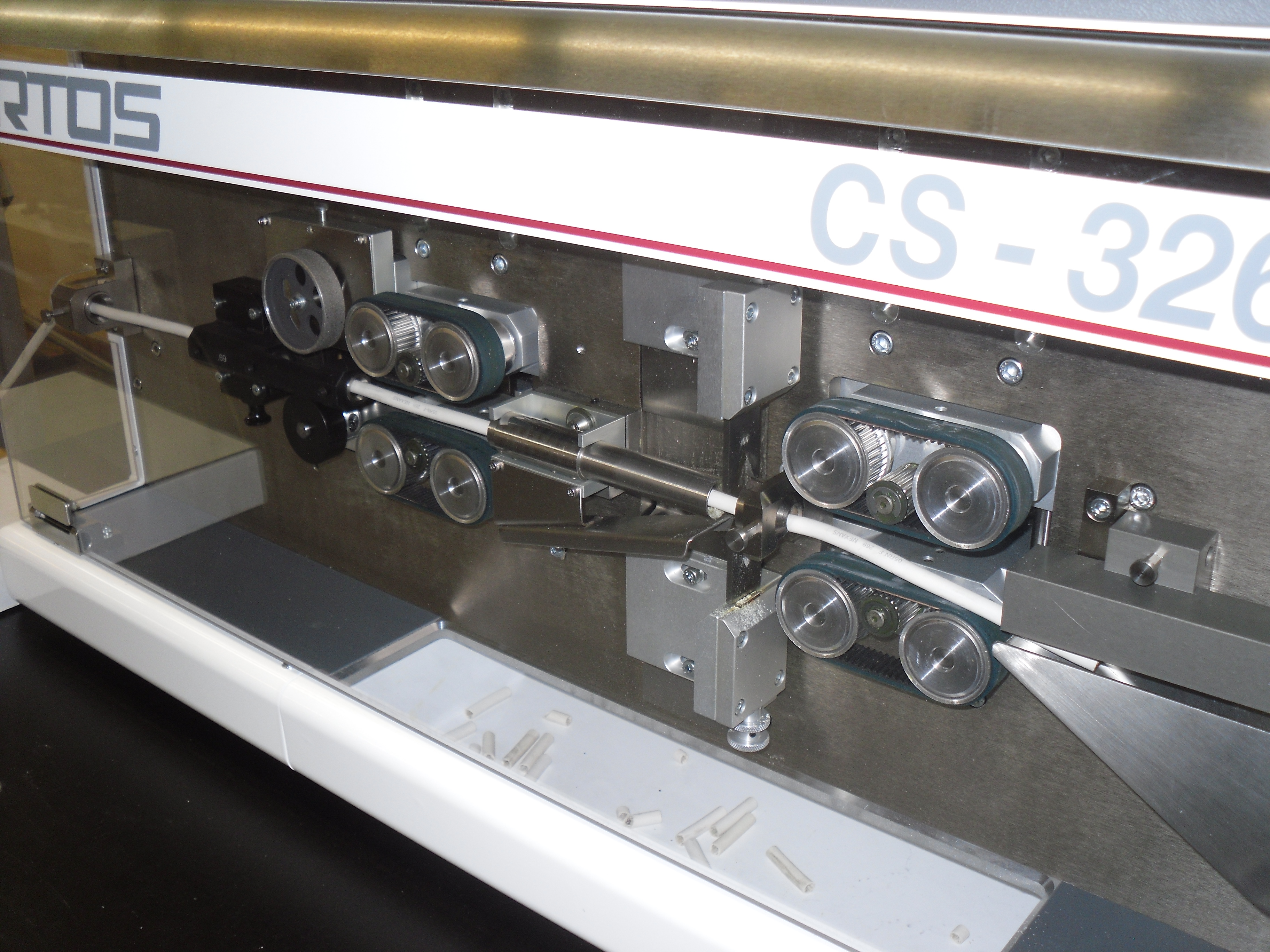

- preparing the cable (cutting, stripping, crimping)

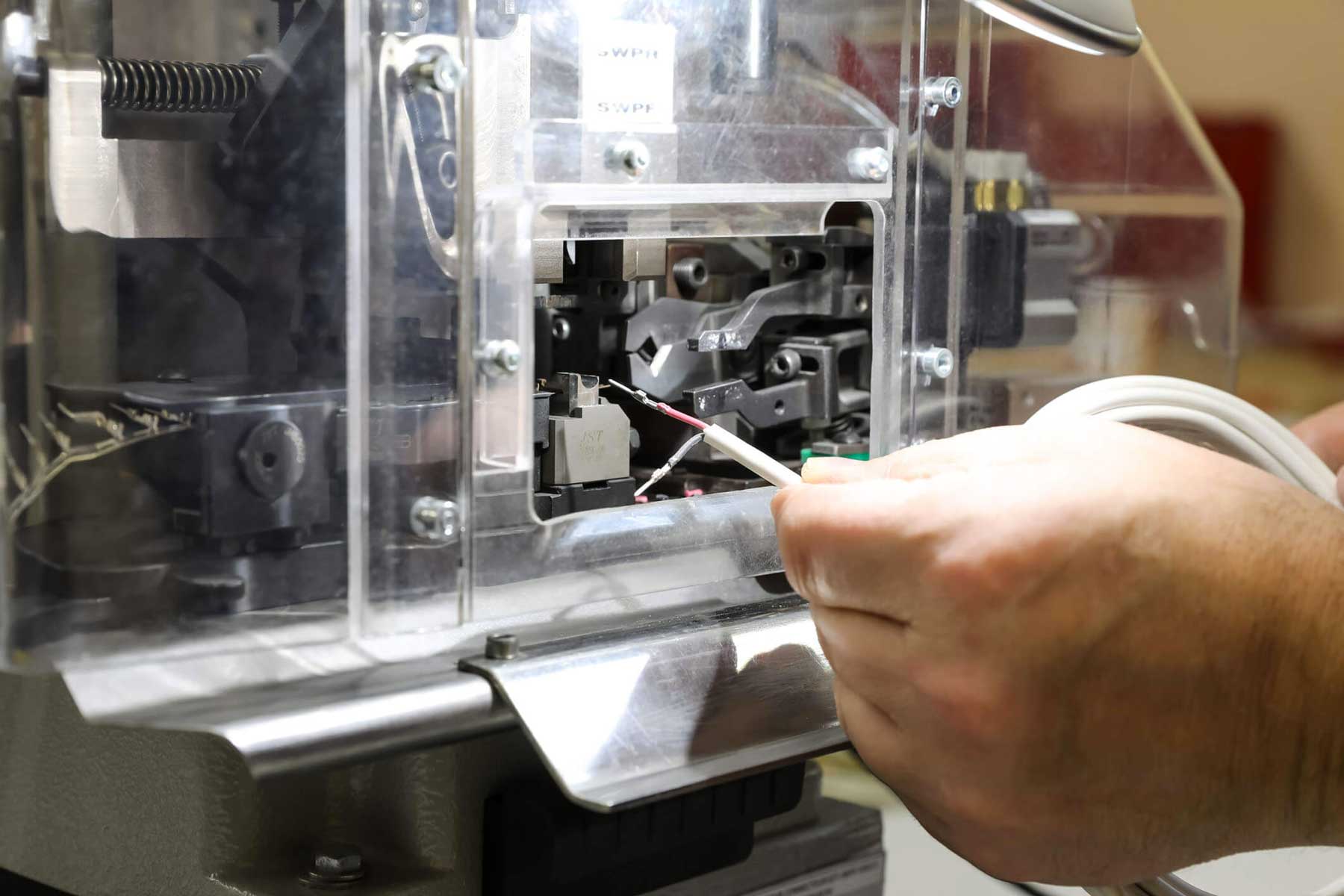

2. Assembling the connectors:

- assembling the connectors,

- installing additional parts (attached),

- inserting and laying cables.

3. Quality control:

- compliance tests for the ordered products,

- tests for the proper functioning of the connectors,

- tests for resistance to wear.

As a value-added service, the production of connected technical parts is offered to our customers to meet specific orders.